Wichita is often billed as the “Air Capital of the World” and, after spending a aviation-filled day on the ground there, it’s hard to argue. The claim isn’t exaggerated but rather an accumulation of facts — decades of aircraft manufacture, test and restoration; a dense cluster of suppliers and OEMs; and a university research engine that feeds industry with innovation and qualified hands. Walk the ramp at the Kansas Aviation Museum, wander through a Bombardier hangar or spend an afternoon at NIAR and the signs are there for all to see: this is a place where aluminium, composites and ideas have been married, repaired and reinvented for more than a century.

But “Air Capital” also describes the city’s pervading culture. Wichita’s identity is woven through with aviation as surely as its wheatfields gave the city its university mascot. There’s a proud, practical lineage here — B-29s, Beechcraft, Cessna, Learjet, Spirit and, today, Bombardier and a thriving test-and-repair ecosystem — that has kept skilled machinists, engineers and innovators in one place for generations. The result is not just a production line but an ecosystem: museums that preserve the story, universities that push the envelope, private firms that refine the craft and local diners where pilots can watch the next craft touch down at an airfield restaurant.

Kansas Aviation Museum

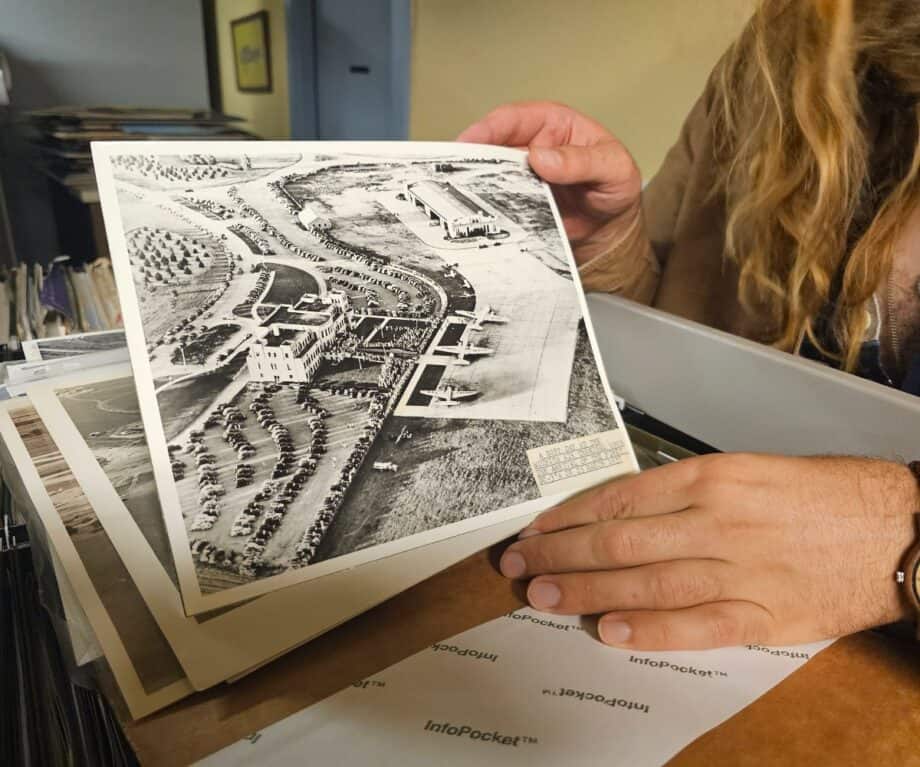

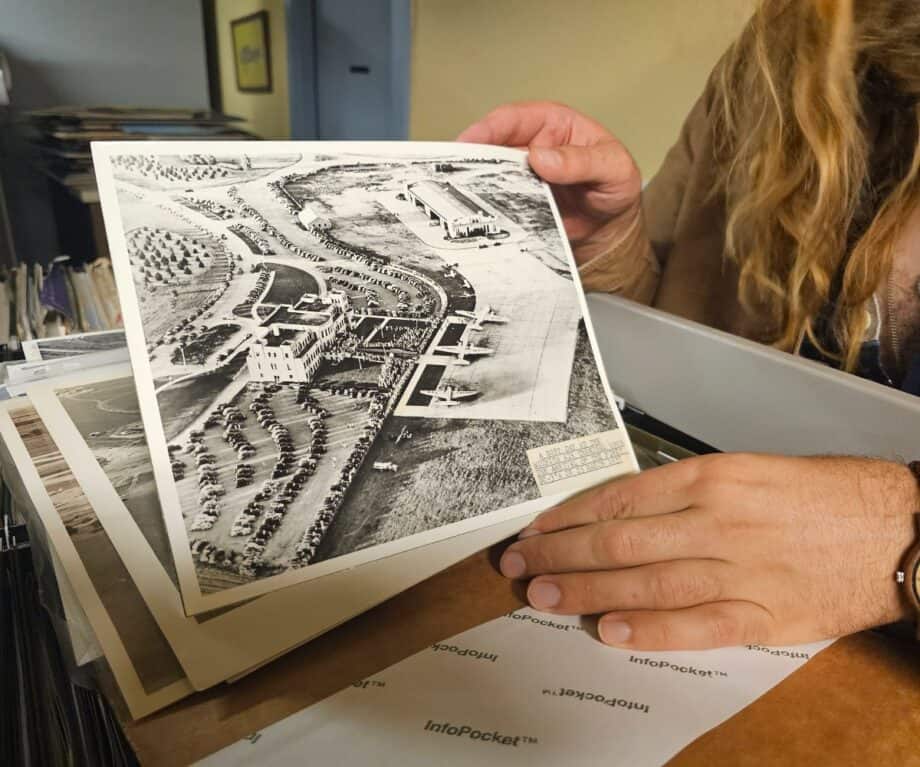

The Kansas Aviation Museum sits in a handsome 1930s terminal building and feels, immediately, like a city’s single-room memory. The building itself—an Art Deco municipal airport terminal—anchors the collection.

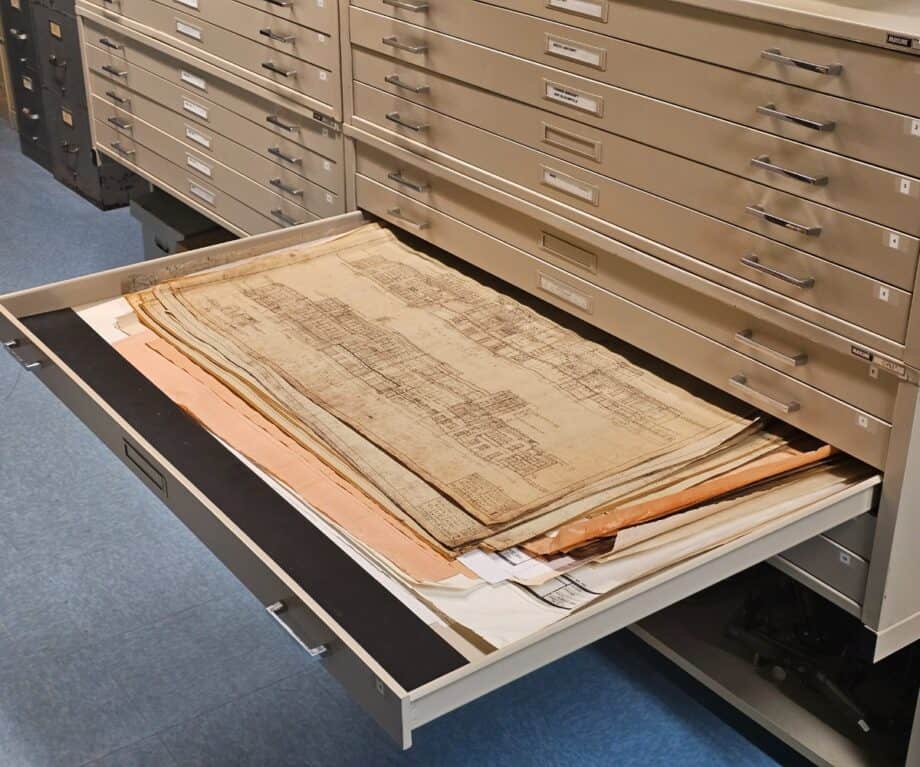

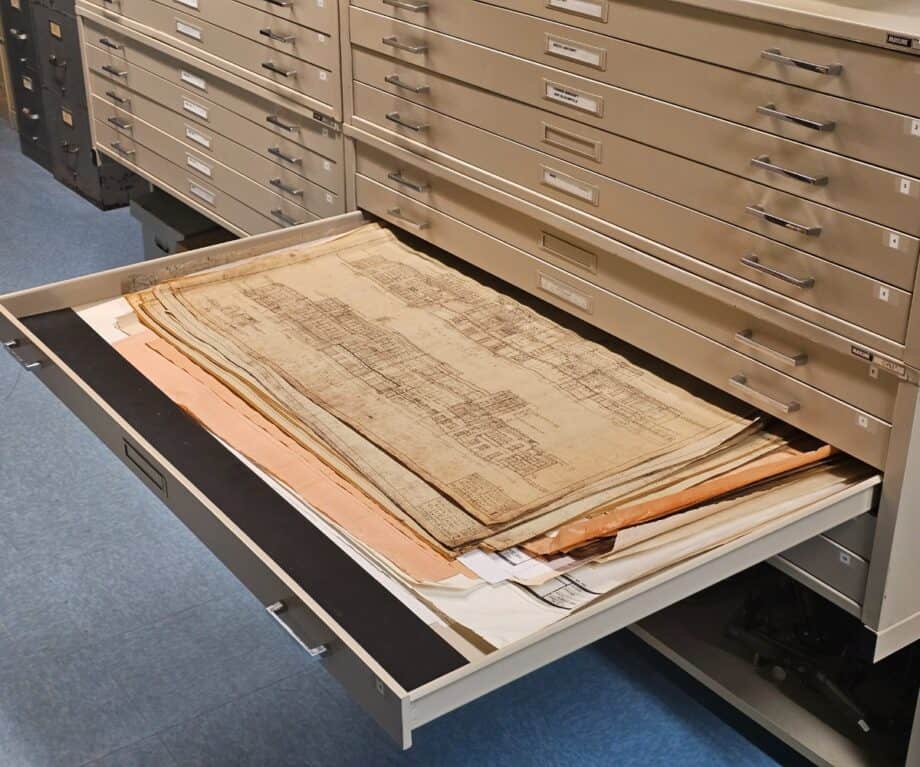

One of the first things we’re told is that the FAA archives for every plane until they moved to a digital system – 3 million records in toal – are stored at the museum. Incredibly, there are 200,000 artefacts, and these archives count as just one!

The museum’s exhibits trace Wichita’s contribution from early Swallows and Stearmans through wartime production and on to business jets and modern composites.

My visit was part museum-tour, part small revelation, and I had the opportunity to clamber inside a Boeing KC-135 Stratotanker, an American military aerial refuelling tanker aircraft used in the Vietnam War, as well as in later conflicts such as Operation Desert Storm (an aerial bombing campaign against Iraq in 1991).

Interestingly, this is the only privately owned KC-135 in the world. (They are usually still owned by the military but this one isnt.)

My visit concluded with a visit to the control tower from which I could see a series of Boeing 737 MAX fuselages in the distance. Located next to the museum is Spirit AeroSystems, one of the world’s largest manufacturers of aerostructures and a key supplier to Boeing.

Spirit builds the fuselages for the Boeing 737 MAX at their Wichita facility before they are loaded onto special railcars to be transported to Boeing’s final assembly point in Renton, Washington.

NIAR at Wichita State University

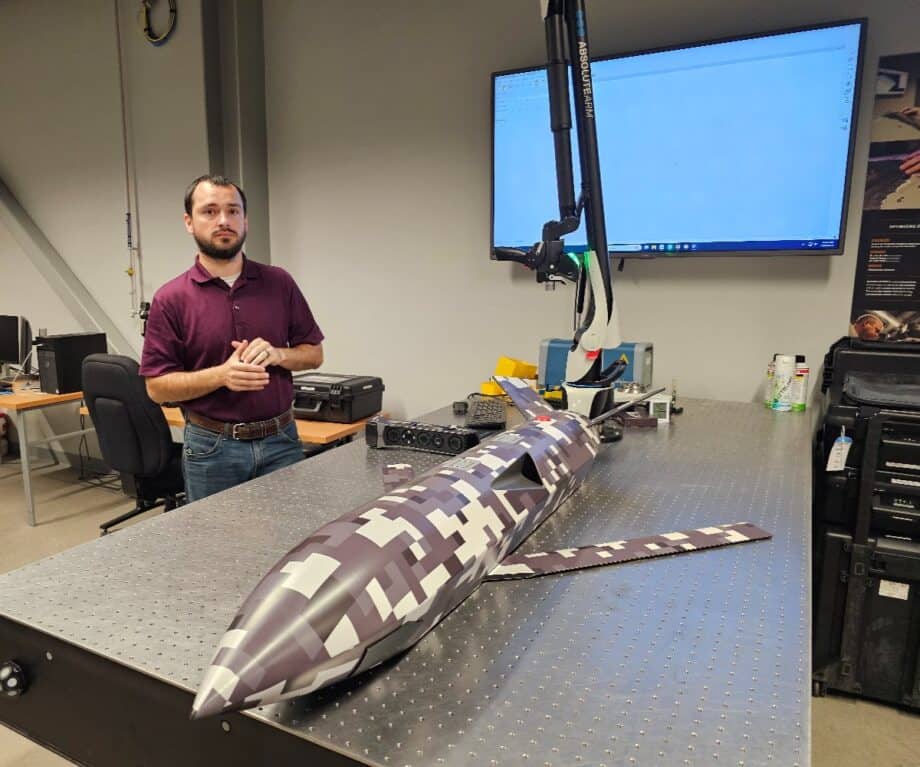

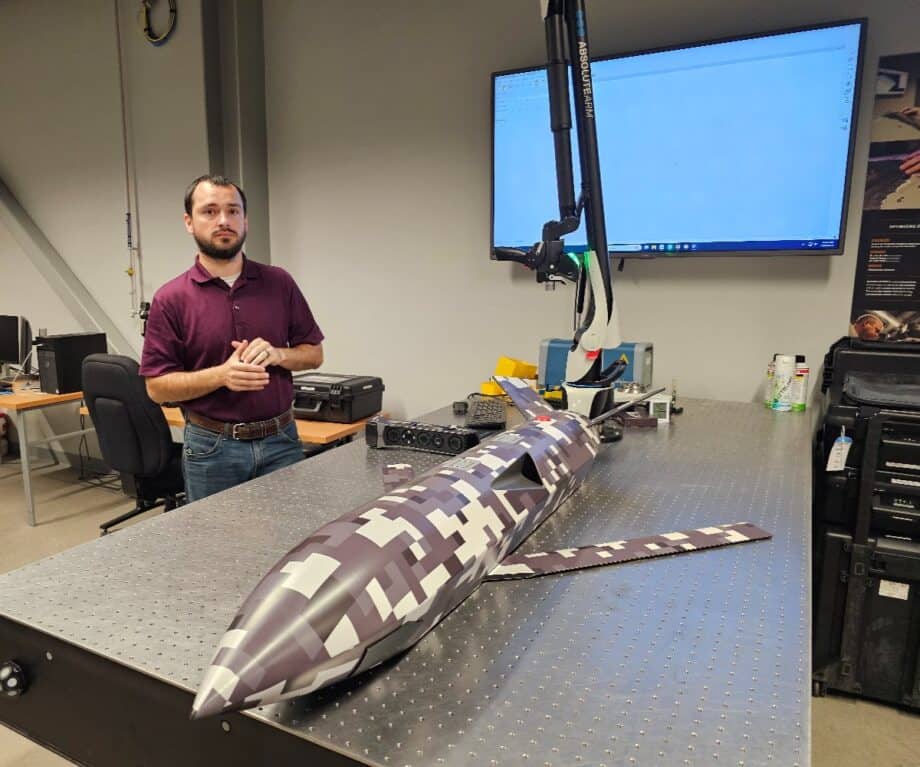

NIAR—the National Institute for Aviation Research at Wichita State University—is where Wichita’s scrappy manufacturing past meets twenty-first-century R&D. NIAR is a large, multifaceted test and development hub: think tensile testing, composites certification, wind tunnels, additive manufacturing labs and automation centres that exist expressly to push prototypes to certification and into production.

A memorable, delightful and slightly surreal moment was being greeted by WuShock—the university’s amusing mascot, a “muscle-bound bundle of wheat” that, in Wichita vernacular, symbolises the region’s agrarian roots and no-nonsense grit.

Two NIAR details stayed with me. First, their additive-manufacturing (3D printing) work: prototypes and flight-worthy parts are now being printed, tested and certified—technologies that were once experimental are now feeding both aerospace and non-aerospace applications. (I saw examples of work that extend to medical implants and structural components). NIAR’s labs don’t treat 3D printing as a novelty but as a certifiable manufacturing path.

Second, the robotics and automation divisions felt less like a science-fair and more like an advanced assembly line of the future: automated cells for handling components, automated inspection rigs and a dedicated robotics centre tackling problems from material handling to complex assembly.

We were shown an advanced gearbox-assembly facility—small, precise, and clearly designed to scale— largely automated, but with some human input.

Stearman Airfield Bar and Grill

If NIAR is where Wichita builds its aviation future, the Stearman Airfield Bar and Grill is where it celebrates its past.

Situated beside a private airstrip, this interesting venue puts you within yards of arriving and departing light aircraft. A living theatre, if you like, for aviation enthusiasts.

I ordered the Stearman Burger and watched pilots taxi between bites. It’s comfort food that knows its audience – pilots and enthusiasts, brunching families and anyone who finds being that close to a taxiing Cessna infinitely calming.

Everything you need to plan your trip in 2025

Bombardier

Bombardier has made Wichita its US headquarters for certain operations and continues to use the site for service, testing and defence work; the campus has grown from a few hangars to many, and its presence signals that international OEMs still value Wichita’s supply chain and workforce.

Background checks for our special, private tour are conducted at reception where a custom-made Learjet Chopper motorbike, first unveiled at a motor speedway event some 20 years ago, is the talking point for any new visitor.

From there, we were taken through defence modification areas—highly secure spaces where bespoke changes are made to aircraft systems and installations. Understandably, photography was not permitted inside these zones – a reminder that some wings of the industry remain rightly and tightly regulated.

Bombardier also operates flight-test and certification activity in Wichita and hosts significant maintenance, repair and overhaul (MRO) capacity. We were guided through the paint room and the wheel and tyre shop where some 4,200 wheels are serviced or repaired annually, many for NetJets, and into a customised park trailer used to monitor flights that go beyond the speed of sound.

The latter could scan 200 miles around it with its fixed antennae at Wichita, or up to 90 miles with mobile antennae. We even went inside a Bombardier Global 7000 esimulator as part of our visit—an uncanny, compact taste of what flight crews train for.

Our visit finished on a nostalgic high note and in an area where we could once again take photographs. The Classic Lear Jet Foundation’s restoration of the very first customer-delivered Learjet (serial 23-003) is being overseen on the campus, in Building 14—the former Learjet delivery facility.

The restoration is a labour of love sitting within a modern industrial context: volunteers and Bombardier staff collaborating to return a 1964 landmark to life. It’s symbolic—Wichita doesn’t simply make planes; it perpetuates the legacy, further cementing the city’s deserved title of ‘Air Capital of the World’.

So, there you have it. Wichita’s claim isn’t just marketing hype but rests on tangible pillars—historic manufacturing, OEM presence, a university R&D engine and a dense MRO and supplier base.

Our insights were made possible through hosted visits to the Kansas Aviation Museum, NIAR, Stearman Airfield Bar and Grill and Bombardier as part of the TBEX Wichita travel blogger conference, supported by Visit Wichita and with transport between the venues provided by Harmony Charters and Travel.

If you love aviation, or simply appreciate the romance of skilled hands shaping metal into meaningful motion, Wichita is worth the detour.

Paul Johnson

Paul Johnson is Editor of A Luxury Travel Blog and has worked in the travel industry for more than 30 years. He is Winner of the Innovations in Travel ‘Best Travel Influencer’ Award from WIRED magazine. In addition to other awards, the blog has also been voted “one of the world’s best travel blogs” and “best for luxury” by The Telegraph.

Did you enjoy this article?

Receive similar content direct to your inbox.

Please enable JavaScript in your browser to submit the form

Please visit:

Our Sponsor